Engineering Services

Professional Engineering

As a licensed professional engineering firm, we can provide a full service design booklet with P.E. stamped drawings and reports. This can be for a start from scratch project or re-evaluating existing structures and equipment. Although we have a wide range of experience, we take our responsibilities of professional engineering very seriously. DLA Aero is not afraid to pass on a project if it requires professional engineering capabilities beyond our expertise and we will not compromise our integrity in the name of profits.

Product Design and ConsultingDLA Aero can lay out a product design road map to take your idea step by step from concept, to prototype, to validation, to production ready drawings with manufacturing plans and vendors.

We can also provide you with feedback on your designs to reduce costs, improve manufacturability, and optimize performance. |

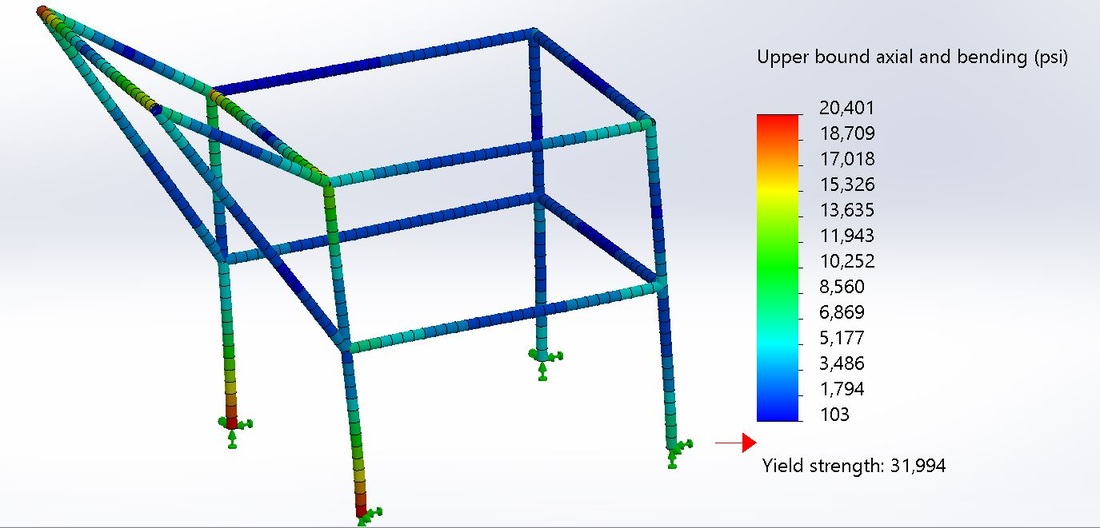

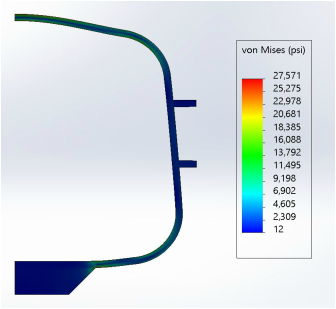

Finite Element AnalysisStandard stress analysis is the most common form of FEA. These simulations provide stress levels found in components under specified loading conditions. This information is used to provide factors of safety, make material selections, and specify safe working loads.

2D Simplifications2d analysis capabilities significantly reduce computational times for components with uniform cross sections.

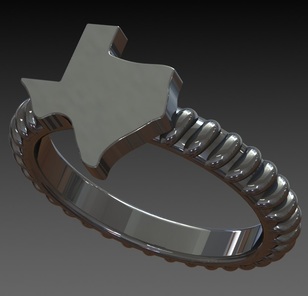

RenderingDLA Aero can provide photorealistic renderings of your parts and assemblies. These images can be used for marketing materials and product proposals when prototypes are time or cost prohibitive.

|

Fatigue AnalysisFatigue analysis predicts the expected life of a component under specified load conditions. This information can be used to set up preventative maintenance cycles and avoid catastrophic failures.

Dynamic Motion AnalysisDetailed motion analysis provides detailed information about your mechanical system’s performance. Output data includes reaction forces, mechanical efficiencies, natural frequencies, and kinematic parameters.

Thermal AnalysisThermal analysis shows how a component will react as a result of temperature changes. This is extremely important for precision assemblies to ensure that parts will not bind our come apart during operations. This type of analysis can also display the temperature distribution through a part or assembly as a result of a known heat source.

Drop TestingDrop test simulations predict the effects of dropping a component from a specified height or into a fixed wall at a specified speed. For consumer items such as cell phone covers, this is often the best measure of a product’s performance.

|